Tests carried out to analyze, evaluate, verify and improve the reliability of products are collectively referred to as reliability tests. Broadly speaking, any test related to the failure (failure) effect of a product can be considered a reliability test. The chivalrous reliability test often refers to the life test. The purpose of rotary bonng/tapping/cutting special machine reliability test is:

Based on the reliability data obtained in the test, the observed value of the reliability of the product is obtained by proper statistical processing, so as to evaluate and check the reliability of the product.

The reliability selection and acceptance of batch products are carried out to ensure that the products meet certain reliability indicators within the specified use time.

Through the test results, product failure analysis is carried out to expose the weak links in product design, manufacturing, maintenance and management, find out the causes of failure, and put forward improvement measures to provide a basis for product development and design, so as to continuously improve the reliability level of products.

Since reliability test is an important means to ensure and improve product reliability, reliability test technology has been greatly developed in the past 30 years, and more than 100 test methods have been used. Even if it is the same product, in different life cycles, for different test purposes, the method is not the same. Reliability test is more time-consuming and expensive than conventional test, and the reliability test of mechanical products is even more expensive. Therefore, the study and use of appropriate test methods is not only conducive to ensuring and improving the reliability of products, but also can greatly save time and cost, so as to promote the reliability work in all walks of life in-depth development.

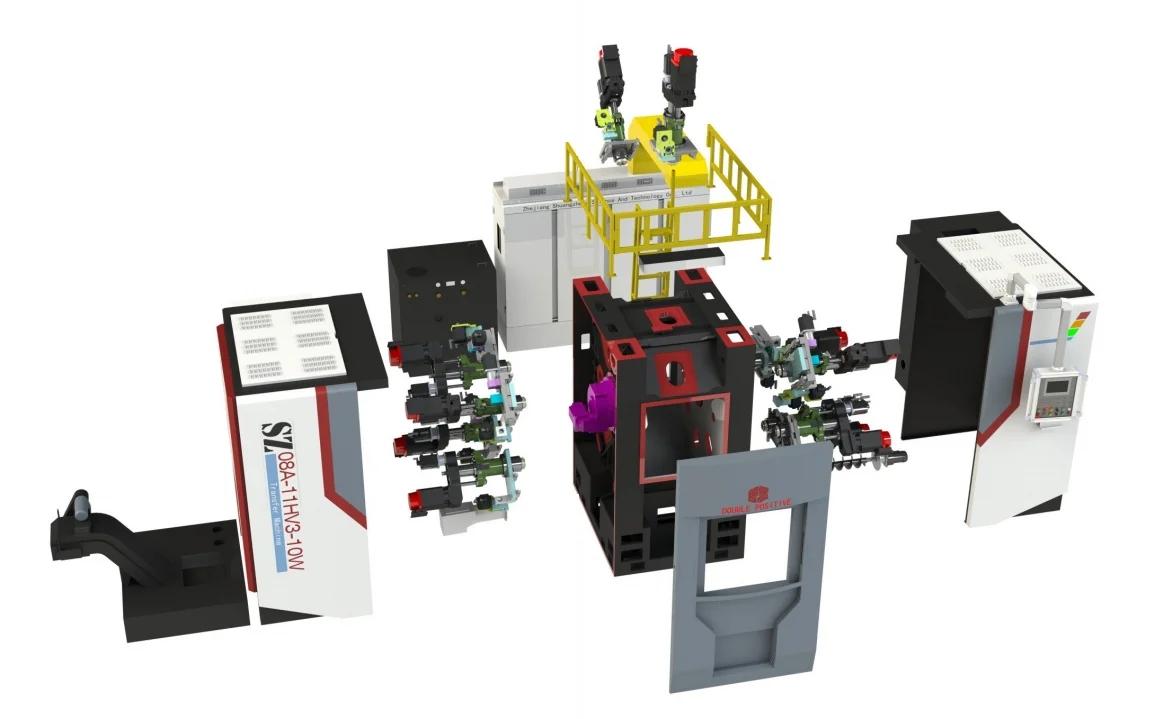

rotary bonng/tapping/cutting special machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html