In the field of industrial manufacturing, integrated transfer machine are a common and important equipment for processing various parts and products. However, due to the long running time and high intensity workload, the integrated transfer machine is prone to various failures, affecting the production efficiency and quality. Therefore, effective fault management is essential to improve production efficiency and ensure product quality.

First, failure prevention: this includes regular maintenance and maintenance, regular inspection and cleaning of integrated transfer machine.

Maintenance personnel should perform regular maintenance according to the equipment manufacturer's instruction manual and ensure that the equipment is in good working condition. In addition, regular inspection and cleaning can help find potential signs of failure, and take timely measures to repair it to avoid the occurrence of failure.

Fault diagnosis: When the integrated transfer machine fails, it is very important to diagnose the problem quickly and accurately.

In order to achieve this, maintenance personnel need to be familiar with the structure and working principle of the machine tool, and have the corresponding troubleshooting skills. They can determine the root cause of the failure by observing, listening to abnormal sounds, and using diagnostic tools. Once the fault is diagnosed, maintenance personnel can take appropriate repair measures to minimize downtime and production losses.

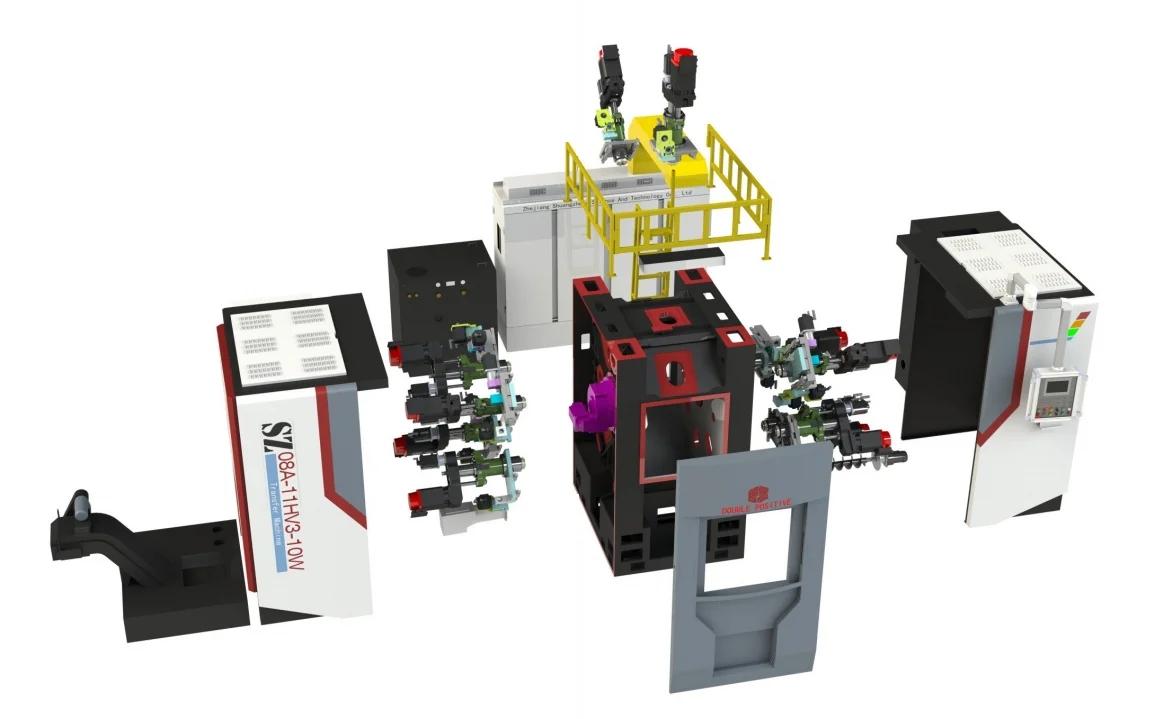

integrated transfer machine fault management skills

Third, fault repair: After determining the cause of the fault, maintenance personnel need to take appropriate measures to repair.

This may involve replacing damaged parts, adjusting machine parameters, recalibrating or upgrading software, etc. It is important to ensure that the fix complies with the relevant standards and specifications, and that it is tested and verified before it can be put back into production.

In addition to the above fault management steps, effective fault recording and analysis is also a key step.

Maintenance personnel should set up a detailed fault record, including the time, cause, remedial measures, and effect of the fault. These records can help identify recurring patterns and trends in failures so that preventive action can be taken. In addition, failure data can be analyzed with data analysis tools to identify potential improvement opportunities and improve equipment reliability.

In a word, integrated transfer machine fault management is a key problem in industrial manufacturing. Through effective fault prevention, fast and accurate fault diagnosis, timely and effective fault repair, and detailed fault record and analysis, the impact of faults on production can be reduced, and the reliability and production efficiency of equipment can be improved. Therefore, enterprises should pay attention to fault management, and invest enough resources and training to establish a professional maintenance team to ensure that the integrated transfer machine can run stably and efficiently.

integrated transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html